August 1st

August 1st marks yet another important time on the Winery calendar. The first berries are threatening to turn colour, faint blasts of bird bangers can be heard in the distance, and our cherished new barrels are starting to board ships in France. The anticipation is palpable!

Winemakers are busy working out the logistics of the coming harvest, while Viticulturalists can be spotted zooming around the Peninsula, horse trading for the best fruit. “Who’s got Pinot Gris? Who needs Riesling? Who’s on first?” It’s a frenzied time for all involved. Grape growers can just work hard, pray for good weather, and hope that all their fruit will make the grade.

In the vineyard, fruit exposure and crop load management are the focus. These are achieved through cluster thinning, strategic leaf removal and timely Botrytis control measures. My goal in the tight-clustered varieties (Pinot Noir, Pinot Gris, Sauvignon Blanc) is thinning them down to a point where each bunch has some elbow room within the canopy. This allows space for cluster expansion and helps alleviate potential “hot spots” for rot. It’s a finicky and costly undertaking, but I’ve learned the hard way that it’s essential to producing quality wine.

The recent stretch of hot and dry weather in Niagara has set us up for what could be a solid vintage. As always, fall conditions will be the ultimate judge.

The Longest Row

Where do the days go?

Every year, right around this time, I shift from basking in the joys of summer to flat out panic. Days are spent trying to motor through jobs in the vineyard, but soon the stark reality sinks in. There just aren’t enough days left before harvest to complete the monster list of tasks.

I find myself in a row of Pinot Gris on this hot Sunday, trying to rationalize how I seem to get into this mess every year, yet somehow manage to get most of the work done. This brings no comfort. The vines just keep growing (even on weekends). There is minor satisfaction in each row of thinning and shoot positioning that I get through, but no time to really enjoy it. I seem to remember more enjoyment in years past. Perhaps this is tied to the fact we now have a winery occupying a large portion of our time. As the sun beats down and I feel the sting of sweat in my eye, I begin to second guess why we decided to start a winery in the first place. Growing grapes alone was sooo much easier. No retail hours, no Interac, no problem!

Just as my self-pity hits a fevered pitch, and I’m convinced that I’ll never finish thinning this unbelievably long row of Pinot Gris, I sense something beside me that causes me to jump with fear (only those who have been surprised out in a vineyard will truly understand my terror). I went from mellowly singing along with John Denver to actually shrieking like a female punk vocalist. Quickly wheeling around I found myself face to face with….what is that?….a coyote wearing sun glasses? Alas no, it was only my Dad coming to aid his slightly heat-stroked son. Without fail, the shock of abruptly meeting someone or something amid the tranquil cocoon of music and vines always makes me jump.

Thankfully, this was just the spark I needed. Together we finished that marathon row and then hiked back to the barn for lunch. Upon arrival, Wilma informed us that we had just missed out on a “crazy Shiraz flurry” and delighted to tell us how much she enjoyed tasting wines with the exuberant group. The excitment on her face brought a smile to mine.

The reward of opening a winery was never more clear. How selfish of me to think of it as a burden, even on this grueling day. Five Rows started as a hopeful brand but has evolved into our lifestyle. For this brief moment in time, we are able to achieve success together as a family. Despite our foibles, the jobs eventually get done and wine seems to magically disappear out the door. I’m increasingly aware that our current arrangement is unique, and not one that can last forever. Therein lies both the paradox and the beauty of Five Rows.

Let’s all enjoy this “Shiraz flurry” while we can.

2008 Five Rows Pinot Noir Vinification Notes

2008 Five Rows Pinot Noir:

Now that we’ve been at this venture for a few years, it’s interesting to look back at my old blog entries upon the release of a new wine. This entry from October 6, 2008 aptly tells the story of our 2008 Pinot Noir:

“Vintage ‘08 is upon us and to this point things have been…well…in a word …WET!! Enough rain already. I mean just when I thought we were in the clear we got doused by the remnants of a hurricane, and for the record: I don’t like Ike. Thankfully, the last couple of weeks have more than made up for the rain, with plenty of sunshine and perfect ripening conditions for the early varietals.

As per usual, the “Heartbreak Grape”, Pinot Noir, lived up to its moniker and provided lots of nervous moments and second guessing. In fact, one day in the vineyard while pondering a harvest timing decision, I found myself singing aloud to the Clash hit “Should I Stay or Should I Go”. The Pinot were clean but slightly underripe, with threatening weather on the horizon (“If I go there will be trouble / And if I stay it will be double”). Ultimately, we decided not to pick and wait out what suddenly became Hurricane Ike. All the water led to some berries actually splitting and roused us into action. Led by a Pinot-loving mother hell-bent on saving her crop, the three of us spent two mind-numbing days cutting out individually split berries and underripe clusters. On September 16th and 17th we finally hand-picked our first two tonnes of fruit. In the end, what came in was ripe, clean (thus receiving the Wilma stamp of approval) and fermented into some really intriguing stuff. I experimented with a new yeast strain this season called W15, which after pressing today, is the early favourite to put into our 2 new Sirugue barrels.”

Fast-forward to 2011 and that Pinot-loving mother can be proud of the wine she helped save. The 2008 is reminiscent of many past wines featuring Lowrey Pinot. A classic blend of bright cherry fruit, some floral notes and spice dominate the nose. Flavours of black raspberry and vanilla bean resolve into a pleasingly soft mouthfeel. Tannins are much more approachable than the 2007 Five Rows Pinot Noir at the same stage.

Technical Data: 12.6% alcohol, 5.4 g/L residual sugar, pH 3.45

Price: $50/bottle

Barrels: 5

Production: 106 cases

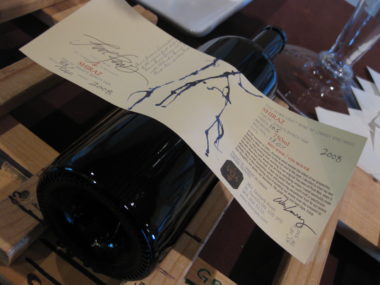

2008 Five Rows Shiraz Vinification Notes

2008 Five Rows Shiraz:

The tale of Lowrey Shiraz began many years ago with a firm handshake. Our relationship as a grower for Creekside Estate Winery started in the late 90’s and continues to this day. Shiraz is a staple for Creekside, grown and vinified to perfection year after year. Given this success, we naively agreed to plant some of these vines soon after our partnership began. Little did we know just how sensitive and vigorous Shiraz could be!

This combination of winter sensitivity and summertime vigor is a challenging prospect for the grape grower. Early in their lives, these vines saw some pretty severe winters that almost led to their extinction in our vineyard. Massive re-plantings and constant re-trunking were needed to restore their numbers. Our hard work and patience was rewarded with some stellar vintages in the 2000s, ultimately inspiring me to take a crack at making my own Shiraz in 2008 (and yes, it will always be “Shiraz” not “Syrah” to us because we planted it for an Aussie!).

The fruit for this wine was harvested on October 23 following some pretty dodgy conditions in the summer of 2008. We initially thinned the vines down to two bunches per shoot, but had to remove additional clusters in the fall, as it became clear that ripening would be a challenge. We hand-harvested about one tonne of fruit from each of our Shiraz clones (7 & 100), then sorted before de-stemming into fermentation bins.

A long cold soak was employed to help with colour extraction and tannic development. I chose to ferment the slightly riper Clone 7 fruit with RX60 yeast, but opted for F15 with the Clone 100 bin. Ferments were carried out at an average pace, with four daily punch-downs.

One new Taransaud barrel, two older French and a lone American oak barrel were used for the maturation process of this wine. Malolactic fermentation was carried out in barrel. After 24 months in oak, the final blend was assembled and allowed to mingle for about 8 more months. This exciting wine was bottled April 6th, 2011.

Aromas: blackberry, black currant, lavender, smoked game

Flavours: dark chocolate, coffee bean, raspberry

Production: 105 cases

Technical data: 13.0% alcohol, pH 3.30, TA 8.55

Price: $50.00/bottle

Don’t Look Now…

Don’t look now, but we have some serious viticultural growth going on out there! Despite the cool and damp conditions, shoots are expanding at a rapid pace. It’s as if the vines couldn’t hold it in any longer and just exploded with life.

As a precaution for potential winter injury, we always leave an extra “insurance” cane on each vine that is not tied down with the others. Initial observations tell me that we can safely go through and remove these extra canes, as most primary buds are appear to be viable. This job will keep my dad and I busy for a couple of weeks – but don’t hesitate to pull me out of the vineyard for a quick tasting should you decide to pop in for a visit!

Come One, Come All

As we head into the summer season, I would once again like to extend an open invitation to all wine lovers. Please do join us for a tasting over the coming months during our weekend retail hours (11-5). It’s an exciting time at Five Rows, as we’ve just released our 2008 Shiraz, 2008 Pinot Noir, 2010 Sauvignon Blanc and 2010 Pinot Gris. The weekend barn traffic has ramped up dramatically in recent weeks and there has been a very positive response to our new products. Anyone wishing to reserve a case, please call or email sometime soon. History has shown us that these wines will not be around very long!

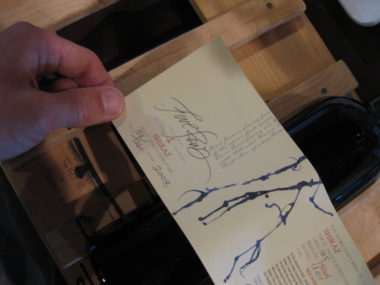

One by One, the Waxing Gets Done

Hot Wax Meets Cool Climate Shiraz.

Is it Spring yet?

It’s depressing to look back at my April 24th post from last year and read just how promising things were looking in the vineyard. In fact, the guy who wrote that passage deserves a good slap in the face for exuberantly rubbing our noses in it. Aren’t you lucky! Two weeks ahead of schedule you say? Well GOOOOOD FOR YOU!

(I apologize for the seething sarcasm, my attitude has not been exemplary ever since a large tree fell onto my car the other day)

Rain, cold and wind are the reality this year. I don’t feel like the buds are too far behind schedule just yet, but we definitely won’t be afforded the 10-14 day head start we saw in 2010. The only advantage of this slight delay might be reducing the window for frost damage over the next few weeks. I’m grasping at straws here.

On the bright side, I’ve actually had my jacket off while tying grapes the last couple of days. What a feeling of liberation! The symbolic removal of one’s jacket and subsequent hanging of it over the top wire is one of my favourite rites of Spring. I almost went “skins” the other day just to stick it to mother nature, but then I realized I might frighten my Aunt Lonna who was out for a stroll with her dogs. The shirt stayed on.

On rainy days I’ve begun the massive task of waxing and labeling our new wines. This job has been expedited by the fact we are nearly sold out of 2009 Pinot Gris and Sauvignon Blanc. Look for a release announcement concerning the 2010 whites and 2008 reds sometime in June. If it keeps raining I should have enough bottles labeled by then!

Exhale

In the past, all of our bottling has taken place offsite at other wineries. There was always a calming sense of security associated with these occasions knowing that we were at a place where this had been done many times before. On the eve of the first ever bottling day at our own barn, these secure feelings were nowhere to be found. I’d spent three months preparing and going over every possible problematic scenario in my head, but doubt still lingered. Would there be enough room to maneuver in our barn? Would the truck fit on our crush pad? Would my bottle choices pan out and, most disturbingly, would bottling icewine prove to be the nightmare I had heard tale of?

All these troubling thoughts kept me awake on the eve of April 6th. I was to be at the barn for 6am sharp the next morning to greet Glenn Hunt and his mobile bottling crew. As the minutes ticked by, I actually started feeling nauseous and got up to take some Pepto Bismol. It didn’t help.

I took solace in the fact that Glenn and Randy do this every day, convincing myself that they must have encountered every conceivable problem and were very seasoned at dealing with anxious winemakers. It was still dark when the truck rolled in and right away Glenn put me at ease when he looked up at the clear sky and confidently stated, “It’s going to be a great day for bottling!” If he could be excited about today, then why couldn’t I?

My second boost of confidence came at the arrival of my father-in-law and brother-in-law who had graciously offered to lend a hand. More important than their braun, they offered a good dose of comic relief that kept us all loose despite the fast-paced dynamic. In times of stress I’ve found that it’s good to surround yourself with hardworking Polish pranksters.

Set-up took far less time than I had anticipated and the first Pinot Gris bottles were rolling off the line by 7:30. Riesling, Sauv Blanc, Pinot Noir, Shiraz and Cab Sauv followed in quick succession. I figured it must be close to lunch at that point and had to look twice when my watch read 10:30! We were flying – but the dreaded icewine still loomed.

Bottling into 200ml icewine glass presents a bevy of problems to the line. The bottles are very tippy, and filling consistently with such a small amount of wine is tricky. Thankfully, our Cabernet Sauvignon Icewine was fairly cooperative and we were able to wrap up bottling by noon. I’d endured months of sleepless nights and we had bottled our entire 600 cases in half a day…the sheer stupidity of this is not lost on me.

I would like to thank Glenn, Randy and all my helpers for making the first Five Rows bottling day a huge success.

Bottling Looms

Perhaps the number one stress for a winemaker on a yearly basis stems from getting his or her wine safely into a bottle. On the surface it seems like such an easy and routine task. In reality it involves a lot of preparation, hair-pulling, and moolah. For small wineries who put “all their eggs into one basket” so to speak, there is no room for error. Every little spill or bottle gone bad is greatly magnified.

Thankfully, there are people who specialize in this field. Mobile bottling lines are a very useful tool for small craft wineries like ours. It does not make fiscal sense for us to purchase a bottling line when the mobile unit can set up and bottle our entire portfolio in one day. Unfortunately, the mobile line does not alleviate the vast amount of prep work and the high cost of raw materials. I’m currently working through an extensive pre-bottling checklist which includes: final blending of wines, protein and cold stability tests, VQA lab and panel testing, coarse and sterile filtration, ordering bottles and corks, floor plan logistics, and shamelessly enlisting family members to help me out on bottling day. Our labeling and waxing is done by hand at a later date, so that removes two finicky variables from the marathon undertaking. The fewer things that can go wrong the better!

The bulk of my worries come long before bottling day and involve decisions like the type of closure to choose and the extent of filtration to employ. The screw cap closure is becoming more and more common these days for good reason. It’s much cheaper and it provides the perfect seal. I thought long and hard about going to a screw cap for this season’s wines, but in the end I’ve opted to remain faithful to good old cork. Call me old fashioned, but it just feels like the right closure for our wines. The potential savings in price by using screw caps is substantial (high grade cork is 70 cents per bottle, while a screw cap comes in around 18 cents per bottle), but the traditional visual and tactile appeal of natural cork still resonates with me. I’m also not convinced that screw caps provide the best mechanism for properly aging my wines.

I’ve talked to a number of our customers about this decision and they are overwhelmingly in favour of cork closures in their premium wines. There is still the perception, albeit unwarranted, that screw caps represent lower quality wine. One only has to look at the increasing number of high-end wines using screw caps to know this is not the case. Aside from cost, a second significant drawback to cork is the inevitable problem of “corked” wines caused by the cork taint chemical TCA. Encouragingly, new technologies and sterilization procedures have gone a long way in reducing the number of “corked” bottles to a manageable level (under 3%). Higher grade corks generally have fewer nooks and crannies for TCA to hide, so we’ve always spent a bit more money for the added security they bring. We’ve been lucky with TCA to this point, but I would encourage anyone who ends up with a “corked” bottle to return it in exchange for a new one.

I’ll probably re-visit this closure debate every year around this time so, as always, I reserve the right to change my mind in the future!

On April 6th we’re scheduled to bottle our 2008 reds (Shiraz, Cabernet Sauvignon, Pinot Noir), 2010 whites and 2009 Cabernet Sauvignon Icewine. The 2008 Shiraz and 2009 Cab Sauv Icewine are first time entries into our portfolio that I’m very excited to have you try. I plan to release these wines early in the summer.