2014 Pinot Noir

Production: 143 cases

Aromas – cherry, floral (violet), red licorice (Nibs), truffle, earth, mushroom

Palate – typical “Lowrey terroir” profile of ripe cherry, pleasing acidity and evolved tannic structure

2014 Syrah

Production: 122 cases

Aromas – wild black raspberry, pepper, cooked meat, tobacco

Palate – ripe red fruit (cherry, plum), savoury core, smooth tannins make it hard not to drink right now

2014 Cabernet Sauvignon

Production: 123 cases

Aromas – wild black raspberry, cherry, bell pepper, violet

Palate – cherry flavoured candy, currant, dark chocolate, structural versatility to enjoy now with meats and cheeses or to lay down for another few years

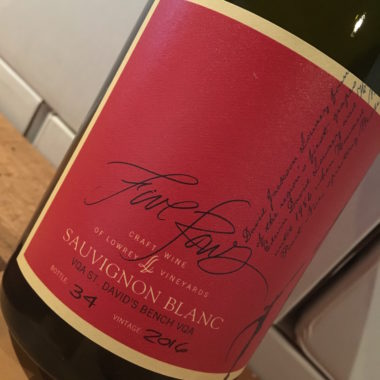

2016 Sauvignon Blanc

Production: 220 cases

Aromas – pineapple, starfruit, grapefruit, peach drink, vanilla bean

Palate – ripe tropical flavours balanced by crisp citrus notes, lingering finish, best enjoyed just below room temperature

2016 Pinot Gris

Production: 110 cases

Aromas – honeydew melon, apricot, whispers of single malt scotch

Palate – full-bodied, balanced, signature Lowrey Pinot Gris texture, tastes like Wilma’s homemade butter tarts

2016 “Jean’s Block” Riesling

Production: 119 cases

Aromas – intense and alluring, floral notes with strong citrus undertones, apple

Palate – zippy acidity, a real depth of flavour, balanced finish, excellent food pairing wine, serve slightly chilled